AI technology is still not widely used

Eyde Digital Day was in April organized at the University of Agder in Grimstad, which is known for its excellent research and education in technology and engineering. The focus of this workshop was the use of AI technology in the process industry. Therefore, I decided to have the artificial intelligence program, ChatGPT, write the article for me.

Here is what it wrote after being fed with some information:

In an AI workshop recently organized by the process industry, discussions were held on how the industry can better leverage AI technology to increase efficiency and optimize the production process. The workshop brought together experts, engineers, and researchers who all shared a common interest in exploring the possibilities that AI technology can offer.

The workshop began with an introduction to AI technology and its applications in the process industry. Participants were presented with examples of how AI technology has already been used in the industry, including the use of machine learning to optimize production processes, predict maintenance needs, and improve product quality.

Shared Experiences

After the introduction, participants shared ideas and experiences on how they are already using AI technology in their own production processes. Challenges the industry faces in adopting AI technology and how to overcome these challenges were also discussed.

One important discussion that arose was how AI technology can help reduce energy consumption in the process industry. Participants shared ideas on how machine learning can be used to optimize production processes, thereby reducing energy consumption. By using data from the production process, one can learn how to optimize the production process to minimize energy consumption without affecting product quality.

Improving the Production Process

Another discussion that emerged was how AI technology can help improve safety in the production process. Participants agreed that machine learning can be used to monitor the production process in real-time and alert operators if there are any errors or abnormal conditions. This will not only help reduce the risk of accidents but also improve the production process by reducing errors and deviations.

At the end of the workshop, the resources required to implement AI technology in the production process and how to ensure that companies have sufficient expertise and technical support to adopt the technology were discussed. It was agreed that it is necessary to increase competence in AI technology and that companies need to collaborate with experts and technology providers to ensure they have the necessary resources to adopt the technology.

The workshop was a great success, and participants agreed that it was a valuable platform for sharing knowledge and experiences about AI technology in the process industry. It is evident that AI technology will play an increasingly important role in the process industry in the future.

Tour of MIL

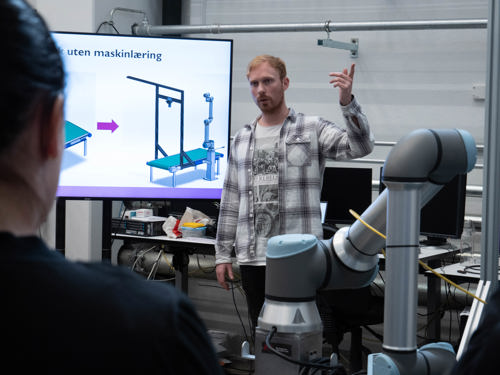

After the workshop, participants were given a tour of the Mechatronics Innovation Lab, which is part of the university's research and innovation environment.

The Mechatronics Innovation Lab is a state-of-the-art research laboratory specializing in automation, robotics, and mechatronics. The lab provides researchers and engineers with the opportunity to develop and test new technologies and systems in these areas. During the tour, participants had the chance to see the latest innovations in automation and robotics and also discuss how these technologies can be used in the process industry.

This tour provided participants with a unique opportunity to witness the latest technologies in mechatronics and automation in action. Participants could also gain a better understanding of how these technologies can be applied in the production process and how they can contribute to increasing efficiency and optimizing processes.

Overall, the workshop and tour were significant events for the process industry in South Norway. They provided participants with an opportunity to share knowledge and experiences about AI technology in the process industry while witnessing the latest innovations in mechatronics and automation in action. With this knowledge and understanding, the industry can continue to develop and improve in a sustainable manner.

HVA SKJER

Se hele kalenderen >-

ARENDALSUKA: Prosessindustrien: Norges bidrag til Europas sikkerhet!

Vitensenteret (VitenUstillingen) -

ARENDALSUKA: Get-together i regi av NEW Node Eyde Women

Kystveien 2. 4841 Arendal, terrassen i 4.etg (Eyde-klyngens lokaler) -

ARENDALSUKA - Global Outlook 2025

Arendal kulturhus, Store Torungen -

ARENDALSUKA: Batterier – Beredskap og bærekraft i en urolig tid

Vitensenteret (VitenUstillingen) -

Arendalsuka: Industrimingling med Prosess21

VitenUtsillingen, Kystveien 2